Sharing notes from my ongoing learning journey — what I build, break and understand along the way.

Autonomous IoT Wind Turbine Management & Wildlife Protection Project

IoT-Based Autonomous Wind Power Plant Management and Bird Protection System

This project is an interdisciplinary study that combines my professional background as an Environmental Engineer with my current training as an IT Specialist for System Integration. The primary objective is to demonstrate how a modern Wind Power Plant (WPP) can be managed autonomously over IT infrastructures, ensuring sensitivity to environmental factors and wildlife conservation.

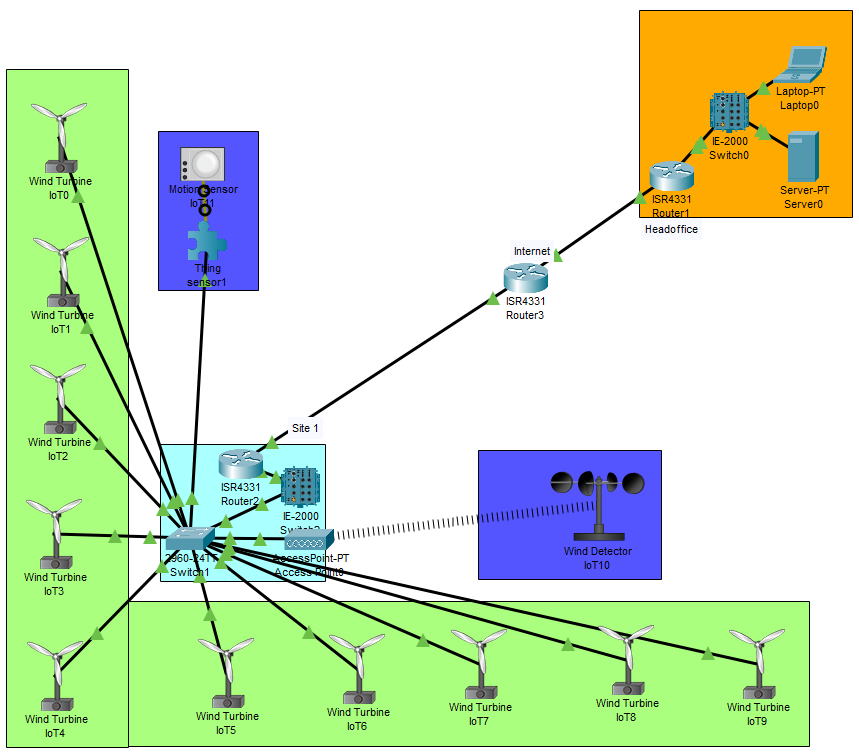

The system is built upon a Wide Area Network (WAN) topology consisting of two main locations: “HeadOffice” and “Site 1” (Field). Data collected from field sensors is processed by a central server to protect wind turbines from destructive weather conditions (such as storms) and to prevent harm to bird flocks migrating through the area. This project serves as a comprehensive simulation example demonstrating how environmental awareness can be seamlessly integrated with Industrial Internet of Things (IIoT) technologies.

1. INTRODUCTION

1.1. Project Background and Personal Motivation

The renewable energy sector is no longer just about mechanical and electrical systems; it has evolved into a discipline centered around data-driven management and Smart Grids.

As an Environmental Engineer, my sensitivity towards ensuring renewable energy sources operate in harmony with nature, combined with my past field experience, drove me to design this project. Currently, as a student of System Integration (Fachinformatiker Systemintegration), I aimed to merge my vision of environmental engineering with the power of Information Technology.

This project is not merely a technical network setup; it is a response from a system integration perspective to the question: “How can we use technology to protect nature?” By blending my past professional expertise with new technical skills, I have structured an autonomous architecture that ensures energy efficiency while respecting ecological balance.

1.2. Problem Definition

The operation of wind turbines presents two fundamental challenges:

- Ecological Impact: The risk of flying wildlife (such as birds and bats) colliding with turbine blades.

- Operational Safety: Preserving the mechanical integrity of turbines during storms or extreme weather conditions.

In the real world, these issues are managed using complex radar and thermal camera systems. However, Cisco Packet Tracer, being a network simulation environment, lacks these visual processing capabilities. The core engineering problem of this project is to model these complex real-world environmental protection scenarios within a logical plane, utilizing sensors, algorithms, and network protocols from an IT specialist’s perspective.

1.3. Project Objectives

- To apply Environmental Engineering principles within a virtual environment using System Integration techniques (Network Management, IoT, Python Scripting).

- To establish a scalable and secure IoT network managed via a central server.

- To transform standard wind turbines into smart edge devices capable of receiving remote commands.

- To develop autonomous decision-making mechanisms for bird detection and storm protection that require no human intervention.

2. SYSTEM ARCHITECTURE AND TOPOLOGY

The system features a hierarchical network structure composed of two geographically separated zones. This structure reflects real-world corporate IoT implementations.

2.1. HeadOffice Network

The HeadOffice acts as the brain of the system. Management and data processing activities are conducted here.

- Central IoT Server (Server-PT): This is the device where data from the entire field is collected, stored in a database, and most importantly, where the automation rules (“Conditions”) are executed. It is configured with a Static IP and provides DHCP and DNS services to the rest of the network.

- Management Terminal (Laptop): The interface used by the network administrator to access the system, monitor sensor statuses, and program automation rules. Access to the server is provided via a web browser.

2.2. Site 1 (Wind Field) Network

This is the field network where energy production and environmental sensing take place.

- Industrial Switches: Used to connect a large number of IoT devices (10 turbines and sensors) to the network. They manage data traffic and ensure device access to the server.

- IoT Devices (Things): Wind turbines (actuators) and sensors fall into this category.

2.3. Network Backbone

The backbone consists of Routers enabling communication between the Center and the Field. These devices route packets between networks with different IP blocks, ensuring that sensor data from the field reaches the central server. The routing protocols used (e.g., RIP or OSPF) ensure that alternative paths are found even in the event of a network link failure.

3. COMPONENTS AND FUNCTIONS

3.1. Sensors (Data Collectors)

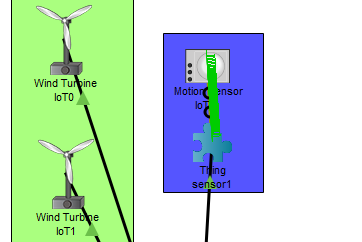

3.1.1. Motion Sensor (Bird Detection System Simulation)

One of the most critical simulation assumptions of the project involves this sensor. In the real world, complex systems consisting of radars and AI-supported cameras are used to protect birds. These systems can distinguish whether an approaching object is an aircraft or a protected eagle.

To model this complex visual processing workflow in the Packet Tracer environment, a Passive Infrared (PIR) Motion Sensor was utilized. In our project, this sensor acts as a proxy. Any motion detected by the sensor is interpreted by the central server as “The camera system has detected a critical bird threat.” This approach allows us to simulate a complex real-world problem at a logical level.

3.1.2. Wind Detector (Anemometer)

This is an analog sensor measuring the ambient wind speed. It generates a numerical value between 0 and 1023 depending on the wind intensity. This data is vital for determining whether the turbines are within their safe operating range.

3.2. Actuators

3.2.1. Smart Wind Turbines

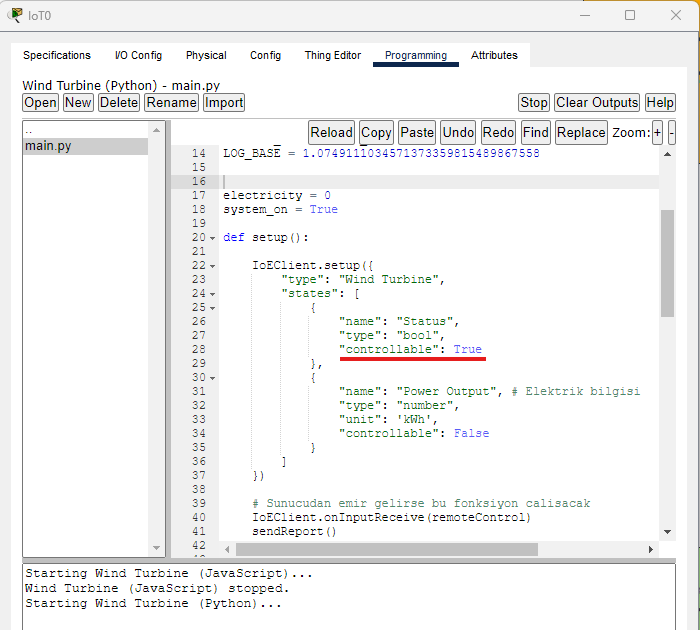

The system includes 10 wind turbines. The default turbine model in Packet Tracer is a passive device that generates electricity solely based on wind speed. Within the scope of this project, these turbines were transformed into active, remotely manageable devices by modifying their embedded Python code.

With the code modification shown in Figure 3, the turbine gains the following capabilities:

- Self-Identification (Setup): When connecting to the server, it reports that it is not just a data-sending sensor, but also has a Status property that is externally controllable.

- Command Listening (OnInputReceive): A function was added to listen for data coming from the server. When the server sends a Stop command, the turbine’s internal electricity generation loop is halted, simulating a braking mechanism.

4. AUTOMATION LOGIC AND PROTECTION SYSTEMS (CONDITIONS)

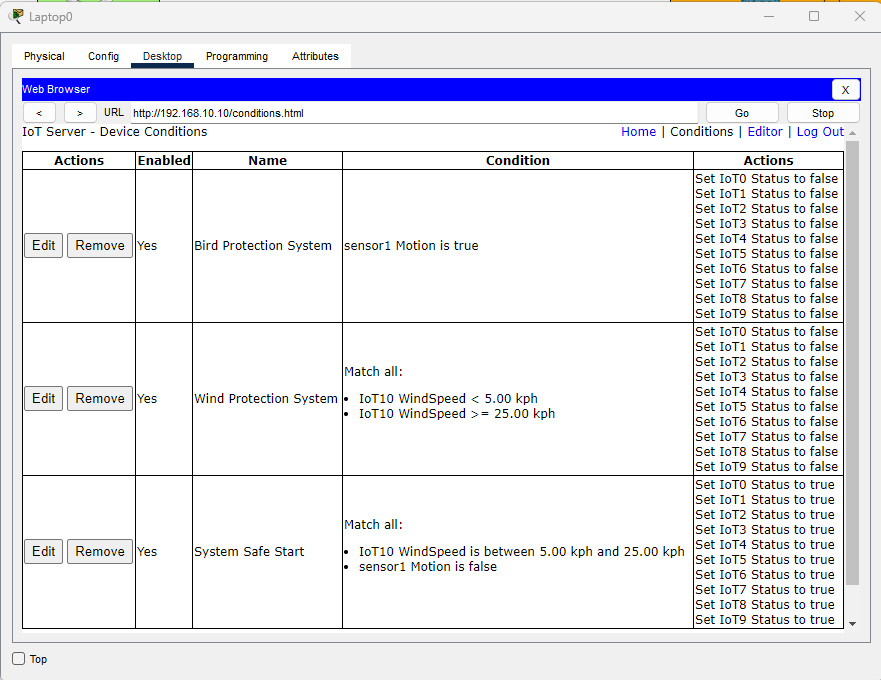

The heart of the project is the set of logical rules, termed “Conditions,” running on the Central Server. These rules convert raw data from sensors into meaningful actions. The system features three main protection and operation rules, meticulously designed to avoid conflict with one another.

4.1. Bird Protection System

This rule is designed to protect wildlife. It has a high priority.

- Logic (IF): IF Motion Sensor (Camera System Simulation) is “True” (Motion Detected).

- Action (THEN): Set the “Status” of all 10 wind turbines (IoT0 – IoT9) to “False” (Stop/Brake).

This rule prioritizes safety by stopping production the moment a bird is detected, regardless of wind speed.

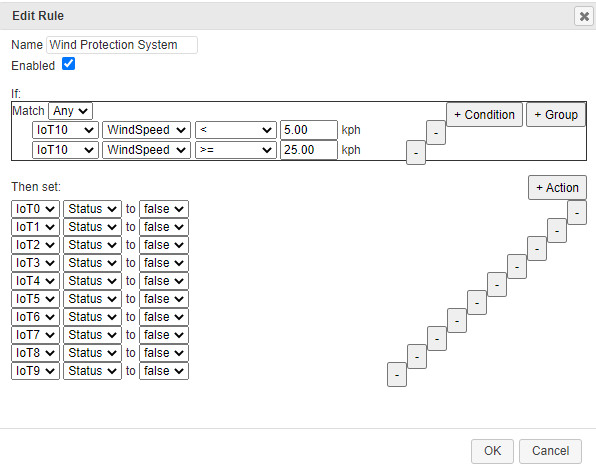

4.2. Wind Protection System (Match Any)

This rule combines two different hazardous conditions under a single rule to ensure the mechanical safety of the turbines. The critical point here is the use of Match Any (OR Logic).

- Hazard 1 (Low Wind / Sub-Cut-in): If wind speed is too low (e.g., < 5 kph), attempting to turn the turbine is inefficient and may damage the gearbox.

- Hazard 2 (Storm / Super-Cut-out): If wind speed is too high (e.g., >= 25 kph), the turbine blades and tower are subjected to excessive load, creating a risk of structural failure.

- Logic (IF – Match Any): IF Wind Speed < 5 OR Wind Speed >= 25.

- Action (THEN): Set the “Status” of all turbines to “False” (Stop/Brake).

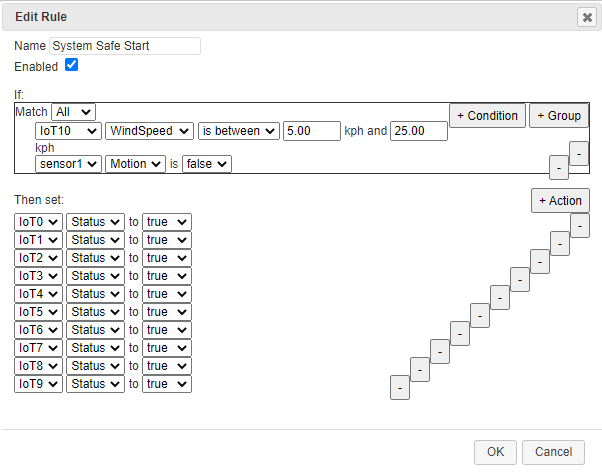

4.3. System Safe Start (Match All)

This is the most critical rule from an engineering perspective. After the system has been stopped (due to birds or storms), the turbines must automatically restart when the danger has passed. However, this restart must occur only if all conditions are perfect.

For example, a bird leaving the field while a storm is still raging is not sufficient grounds for the system to operate. Therefore, Match All (AND Logic) is used here.

- Logic (IF – Match All):

- Wind Speed > 5 (Sufficient wind exists) AND

- Wind Speed < 25 (No storm, within safe range) AND

- Motion Sensor is “False” (No bird threat).

- Action (THEN): Set the “Status” of all turbines to “True” (Start/Begin Production).

Thanks to this rule, the system avoids race conditions (indecision). For instance, the system stops when the wind is at 3 units, and safely restarts when it reaches 15 units (provided there are no birds).

5. SIMULATION AND TEST RESULTS

The designed system was tested under various scenarios using the Real-Time simulation mode of Packet Tracer.

5.1. Test Scenario 1: Bird Detection

While the system was in normal production mode (Wind speed 15 units, turbines spinning), a virtual motion trigger was activated on the motion sensor. Result: Instant data flow from the sensor to the server was observed, and the Bird Protection rule activated in under 1 second, stopping all spinning turbines. When the motion ceased, the system automatically resumed production.

5.2. Test Scenario 2: Storm and Low Wind

By altering environmental variables, wind speed was first set to 40 units (Storm) and then to 2 units (Low Wind). Result: In both cases, the Wind Protection rule successfully activated, braking the turbines. When the wind speed was returned to the safe range, the Safe Start rule brought the system back online.

5.3. Network Traffic Analysis (Simulation Mode)

Analysis performed in Packet Tracer’s “Simulation” mode examined the communication packets between devices.

During the analysis, it was observed that some packets originating from the Switch (ARP or STP broadcasts) were rejected (indicated by a Red X) by non-destination devices. This is normal behavior inherent to Ethernet networks and does not affect the system’s operation. It was confirmed that the actual IoT data traffic (reports sent to the server via TCP/IP) was successfully transmitted.

6. CONCLUSION AND EVALUATION

This project demonstrates how Industry 4.0 and IoT technologies can offer revolutionary solutions in the energy sector, pushing the boundaries of the Packet Tracer simulation environment.

The realized system is not merely a passive structure reading data from sensors; it is a fully autonomous Cyber-Physical System example that perceives the environment, makes decisions, and intervenes in the physical world.

The key success factors of the project are:

- The intelligent modeling of complex real-world camera systems in a simulation environment using logical sensors.

- The transformation of standard devices into smart devices via Python coding.

- The establishment of a safe, stable, and conflict-free automation algorithm through the correct use of Match Any and Match All logic.

This study establishes a solid Proof of Concept for future smart grids and sustainable energy production.